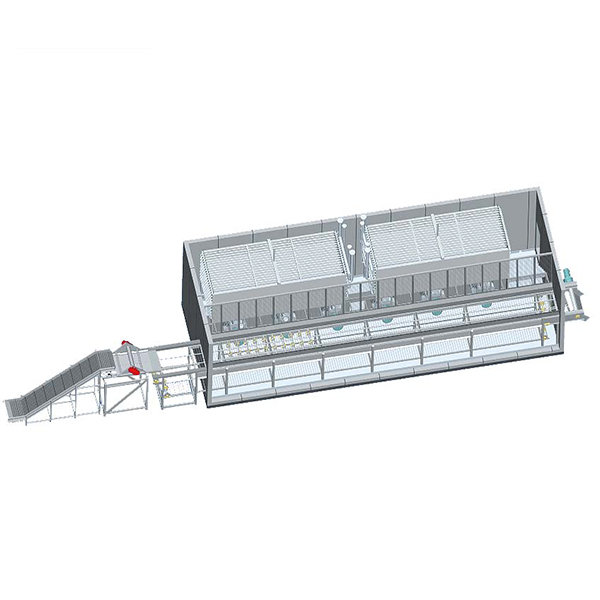

Revolutionize your food processing line with our Industrial Fluidized Bed Tunnel Freezer — the ultimate solution for rapid, uniform freezing of particulate and semi-solid food products. Engineered to preserve texture, flavor, and nutritional value at scale, this freezer redefines efficiency for seafood, fruits, vegetables, ready-to-eat meals, and beyond.

Inside the tunnel, temperatures sit between minus 30 and minus 40 degrees Celsius. Freezing takes only 3 to 15 minutes, though longer times apply to bigger pieces. Berries stay crunchy, shrimp remain tender, while chopped veggies hold their color because of it.

Wherever the design is used, sticking of material gets blocked completely. Freezing for removal means less waste left behind, more than one out of seven pieces kept.

Made of 304 stainless steel – approved for coming into contact with food – the tunnel allows easy cleaning since everything underneath the surface moves into place. Conveyor sections lift out whenever required. Electrical components sit behind shields meant to keep water and dampness away. Each piece follows FDA, EU, and HACCP standards exactly, leaving no room for exceptions.

Power comes from a motor adjusted by a VFD, making the fan run on less juice. Because insulation is applied in thin layers, energy waste drops away. These machines now suck in just twenty percent of the old stuff, cutting monthly payments without fuss.

Five meters might be the lowest point where usage begins. Up to twenty meters could cover what some require. How fast the belt moves changes whenever demand shifts. Depending on what material needs handling, heat management adjusts. When producing only 100 kilograms per hour in small lots, those methods work well. Suppose your business handles much larger moves – say, moving 10,000 kilograms every single hour. In cases like that, suitable choices still remain available.

Whatever the occasion, whether you’re buying for yourself or to distribute, we have it all! Send us inquiry to find out about our volume discounts.